Euromac Punching Machine Software

- Beyond the characteristics common to all EUROMAC punching machines, MTX FLEX 6 shows the following features: 6 D station, of which 3 programmable index stations 360° with an increment of 0.01° (D size). The EUROMAC MTX turret allows you to Choose the Setup you Need and change it anytime you have to.

- Punching and bending machines Euromac is a well known worldwide supplier of machines for sheet metal working, such as CNC punching, bending and notching machines utilizing the most recent technologies and constantly refined by our design engineers to meet the most demanding market requirements for flexibility.

- Euromac’s XT new high performance punching machine, is flexible according to any production requirement. Fully configurable, hydraulic, hybrid, electric, 6 or 12 turret machine. Working area of 3000 x 1500 mm without repositioning. Punching speed: – up to 1080 strokes per minute for nibbling 1 mm pitch. – up to 460 strokes per minute.

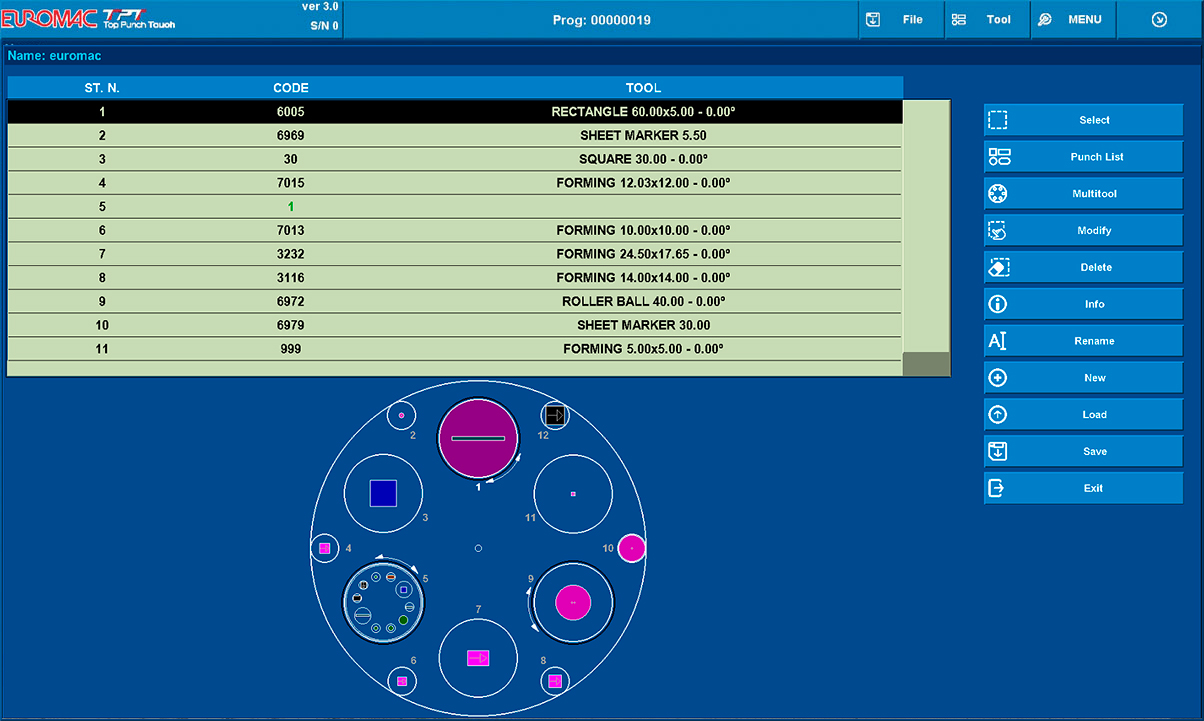

TopPunchTouch® The innovation of Euromac machines now includes their software. In fact, TopPunch® is now available in the touch screen version. This packages maintains all the special features of TopPunch® but, as the name suggests, it runs on a 21.5″ LCD back-lit touch screen.

Punching Arcade Machine

CINCINNATI - June 8, 2020 - PRLog -- Lantek, the multinational pioneer in the digital transformation of the sheet metal and metal industrial sector, announces a collaboration agreement with Euromac, an Italian worldwide supplier of machines for working with sheet metal including CNC Punching, Bending, and automated systems.

Lantek, the multinational pioneer in the digital transformation of the sheet metal and metal industrial sector, announces a collaboration agreement with Euromac, an Italian worldwide supplier of machines for working with sheet metal including CNC Punching, Bending, and automated systems.The agreement enables control of the 'sorting cell' programmed with one of the most cutting-edge robots on the market, the Kuka KR 10, using two punching solutions from Lantek: Lantek Expert PUNCH-PLUS and Lantek Stackmaster. Combined, these solutions enable the automation of the discharge line for parts and their subsequent palletization and storage.

Lantek software solutions are responsible for the whole process, starting with programming the punching machine. Once this task is complete, the machine unloads the parts through a hatch. The parts pass along a conveyor belt until they reach an artificial vision table where a camera detects the position of the fallen part. Lantek software controls the activation and positioning of the robot's suction cups and positions the robot so it can pick up parts while telling it the shape of the part. This helps detect the rotation needed to place it properly on the pallet. Production can be completely unattended thanks to the full control of the punching and palletizing process. This allows automation of the entire production cycle for large volumes of parts.

'The close collaboration between Euromac and Lantek is a significant step towards the full automation of the punching lines and the subsequent palletization of the parts. By using state-of-the-art technology, such as artificial vision or robots, we can maximize production speed and flexibility while improving workers' conditions and safety,' states Francisco Pérez, director of the OEMs channel at Lantek.

Ferrán Villanueva, sales manager at Euromac, highlights the importance of this collaboration. 'For us, this is a great opportunity to use Lantek software for the Kuka KR 10. It will allow us to optimize the processes, reduce times, and achieve an efficient operation while guaranteeing the highest quality and tightest response times from this robot, one of the most cutting-edge on the market,' concludes Villanueva.

###

About Lantek Sheet Metal Solutions

Lantek is a multinational leading the digital transformation of companies in the sheet metal and metal industry. With its patented manufacturing intelligence software, it enables factories to be connected, turning them into Smart Factories. It rounds off its range of services with CAD, CAM, MES, and ERP solutions for companies that manufacture metal parts from sheet metal, tubes, and profiles using any cutting technology (laser, plasma, oxycut, waterjet, shearing and punching). Lantek's U.S. Headquarters are in Mason, OH.

Founded in 1986 in the Basque Country (Spain), one of the main European hubs of machine tool development, Lantek enables the integration of sheet metal and metal processing technologies using the most advanced manufacturing management software. The company is currently the outstanding leader in its sector thanks to its capacity for innovation and commitment to internationalization. With more than 23,700 customers in over 100 countries and 20 offices in 14 countries, it has an extensive network of distributors with an international presence. In 2019, its international business contributed to 86% of its revenue.

For more information, visit: www.lantek.com

Kevin Must

***@lanteksms.com

Photo:

https://www.prlog.org/12825309/1

The innovation of Euromac machines now includes their software. In fact, TopPunch® is now available in the touch screen version.

This packages maintains all the special features of TopPunch® but, as the name suggests, it runs on a 21.5″ LCD back-lit touch screen.

Features

- A larger and more luminous screen

- Updated and simplified layout

- Extremely sensitive Also suitable for being used wearing gloves

- Step-by-step forward and back display

- Available upon demand for the entire range of Euromac machines

- WI-FI integration

Punching Machine Cnc

Easypunch is CAD/CAM nesting software, especially designed for automating numeric control punching machine programming.

Easypunch has an advanced, intuitive and user-friendly interface that improves efficiency during programming.

Easypunch controls autoindex tools, multitool stations and all types of tool, from the standard types to shaping, offset, boring, threading, stamping tools and many other types.

Easypunch gives you the possibility to choose between automatic and semi-automatic nesting, as well as manual, hence granting an outstanding flexibility and optimal performance. The combination of automatic and manual nesting functions (copy, shift, rotation) proves to be an extremely powerful tool.

Euromac Punching Machine Software Download

Easypunch PLUS is an automatic nesting tool that optimises the layout of components on the sheet and offers different options for standard punching operations on regular or irregular workpieces.

Other features of Easypunch:

- Teamwork – This system can operate independently or within a network. Thanks to the floating license option, the system can be accessed by several users.

- Parameters library – The EASYPunch solution has an extensive library of parameters from which users can choose.

- Open Database – Open database where users can find components, production orders, sheets, etc. using criteria such as: material, thickness, customer, date, etc.

Exercise Punching Machine

- Intelligent import/export function – EASY Punch can be connected to all main and currently available CAD systems (DXF, DWG, IGES, DSTV, etc.).

- Integration – EASY PUNCH works with the most commonly used 3D design systems (SolidWorks®, Autodesk Inventor®, Solid Edge®, Catia® and many others).

- Effective time and cost calculation – EASYPUNCH calculates the time and costs per workpiece and per sheet. With this information, users can draft offers, check the volume of work of each machine and print all the reports needed.

- Intelligent import/export function – EASY Punch can be connected to all main and currently available CAD systems (DXF, DWG, IGES, DSTV, etc.).

- Integration – EASY PUNCH works with the most commonly used 3D design systems (SolidWorks®, Autodesk Inventor®, Solid Edge®, Catia® and many others).

- Effective time and cost calculation – EASYPUNCH calculates the time and costs per workpiece and per sheet. With this information, users can draft offers, check the volume of work of each machine and print all the reports needed.